compressed air testing food industry|validation of compressed air : trading Trace Analytics is an A2LA accredited laboratory specializing in compressed air and gas testing for food and beverage manufacturing facilities. Using ISO 8573 sampling and analytical methods, their laboratory tests for . 15 de mai. de 2022 · 加入 TapTap Clash Mini社区论坛,这里有完整细致的Clash Mini游戏攻略,精彩繁多的Clash Mini玩家视频,让你在最火爆的游戏社区找到志同道合的游戏伙伴。

{plog:ftitle_list}

Digital skimming is the act of stealing credit card information .

Trace Analytics is an A2LA accredited laboratory specializing in compressed air and gas testing for food and beverage manufacturing facilities. Using ISO 8573 sampling and analytical methods, their laboratory tests for . Trace Analytics is an A2LA accredited laboratory specializing in compressed air and gas testing for food and beverage manufacturing facilities. Using ISO 8573 sampling and analytical methods, their laboratory tests for . Compressed air is used in a broad range of applications in the food processing industry. In many of these applications, compressed air is in direct or indirect contact with food product, and impurities in the compressed air may contaminate the food product, which can result in changes of color and taste, and reduced shelf life. Also, exposure to bacteria and .“11.5.5.1 Compressed air or other gases (e.g. nitrogen, carbon dioxide) that contacts food or food contact surfaces shall be clean and present no risk to food safety.” “11.5.5.2 Compressed air systems, and systems used to store or .

Compressed air quality is a critical aspect of sanitation in the food industry. While regulation is still in its infant stages in some places, the core desire to protect consumers is enough to warrant regular air testing, as well as to ensure that equipment and processing environments are operating efficiently.High-quality compressed air is critical for providing food products that are not only cost effective to process but safe to eat. Compressed air is a universally accepted power distribution method in industry. The food manufacturing and processing industry uses compressed air in multiple operations. Compressed air provides the energy for pneumatic conveyers that transport .

The process and methods of compressed air testing for microbiological contaminant content is outlined very well in the ISO 8573-7:2003 document. Code or Standard Verbiage relative to compressed air testing IFS, ISO, GRMS Compressed air is identified specifically as a potential risk to be evaluated and monitored as necessary.Our BVAQ Compressed Air Service offering is a unique service to the food industry. Compressed air is an important and major part of most manufacturing and industrial processes and its purity is vital to prevent contamination of the finished product. BVAQ are the first food testing laboratory in Australian to offer this complete service. As an ISO 17025-accredited supplier for end-to-end food testing, we serve all food industry segments with services to meet unique needs. Testing Services; Safety & Quality Testing . CAMTU is widely recognized as the most cost-effective solution for testing compressed air on the market today. Weighing less than a pound and ergonomically .The AirCheck Kit™ K810 is designed for use with manufacturing specifications such as ISO 8573, and other custom specifications testing for particles, water, and total oil. This kit is typically used by food manufacturers, pharmaceutical manufacturers, medical device facilities, and nuclear plants who use low pressure air in their processes and systems.

Compressed air is the food and beverage industry’s “fourth utility” after the big three of water, electricity, and natural gas. The reliability of this fourth utility depends on predictable air pressure, which means even small leaks can come at a high price. . Compressed air leak testing helps coffee roaster easily identify energy .

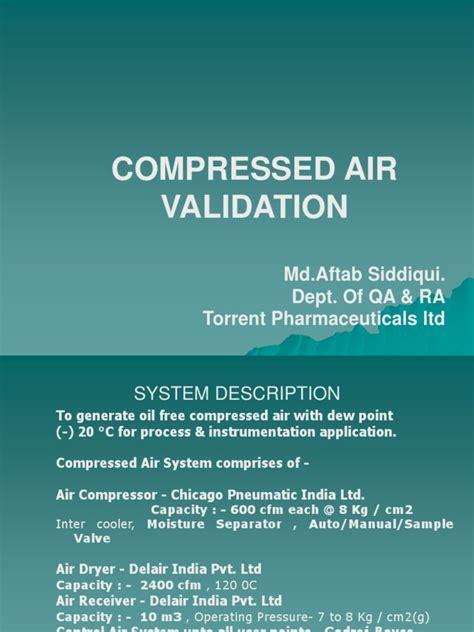

validation of compressed air

SQF requirements include compressed air purity testing for the food, beverage and packaging industry. The SQF code specifies that compressed air used in the manufacturing process shall be clean and present no risk to food safety, and compressed air used in the manufacturing process shall be regularly (annually, at minimum) monitored for purity.Are you looking to learn more about the compressed air industry? Do you have pressing questions about compressed air and gas systems? Look no further! . Introduced in May 2021, this standard includes requirements for annual compressed air quality testing by food processors. Learn more about microorganism growth in compressed air systems here.Compressed air is used in a variety of applications within the Food & Beverage Industry. In fact, nearly every stage of production and handling, from preparation of ingredients to product creation to packaging and shipping may involve compressed air in minor and major operations. Conveyor belts may be pneumatically driven. Automated lines for filling or.important that all types of air systems with potential product safety and spoilage implications are continually monitored. When testing for the microbiological quality of ambient and compressed air, the methods outlined below are air testing strategies that are commonly used: • Sedimentation (settling) method for ambient air monitoring

An oil-flooded rotary screw compressor is a good choice for most food production applications, including powering bottling lines, conveyor systems, sorters and other pneumatic equipment. But with the right filtration, an oil .

According to the Compressed Air and Gas Institute (CAGI) and the International Organization for Standardization (ISO), the three major contaminants in compressed air are solid particles, water, and oil. CAGI .

CHAPTER I--FOOD AND DRUG ADMINISTRATION DEPARTMENT OF HEALTH AND HUMAN SERVICES: SUBCHAPTER B - FOOD FOR HUMAN CONSUMPTION . Compressed air or other gases you introduce mechanically into or onto a component, dietary supplement, or contact surface or that you use to clean any contact surface must be treated in .

iso air quality chart

iso 8573 1 latest version

iso 8573 1 guidelines

The Food and Drug Administration (FDA) regulates the pet food industry. The Federal Food, Drug and Cosmetic Act (FFDCA), requires that all animal foods, like human foods, be safe to eat and contain no harmful substances.Compressed air used in the manufacturing process of pet food should be considered a Critical Factor as it can have a direct affect on the Commercial . Introduction - The Microbial Air Biosphere [1] Air borne microbes are transported via a combination of three methods: spores [bacterial/fungal], water droplets, & biofilms [via sloughing]. Micro-aerosolized droplets are how many members of the microbial world become cross-contaminants via the air mode of transmission. Food borne viral pathogen Hepatitis A .

Standard Baseline Test There are two common tests available for food grade compressed air: 1. ISO 8573:2010; and 2. Microbial testing ISO 8573 This test is the standard test for food grade compressed air. The process samples for total material, oil and water. The report will identify which of class of the ISO 8573 each

Compressed Air Industry Standards - posted in SQF Food: Hi Everyone, We recently ran some Standard plate count, yeast and mold tests and received the following results: SPC 1 CFU/ 15 min SPC 10 CFU/ 15 min Yeast <1CFUs/ 15 min Yeast <1 CFUs/ 15 min Mold 3 CFUs/ 15 min Mold 10 CFUs/ 15 min The compressed air has a 0.1 micron filter on it, and we .

Analysis & Testing. Air Sampling 101. . Good Weighing Practices for the Food Industry. . Food and beverage manufacturers use compressed air for a variety of processes. Unfortunately, when it comes to the quality of this air, compressed air and gas is an often-overlooked utility. Compressed air is a critical utility widely used throughout the food industry. Being aware of the composition of compressed air used in your plant is key to avoiding product contamination. Your task is to assess the activities and operations that can harm a product, the extent to which a product can be harmed, and how likely it is that product harm will occur.This kit is used for industrial breathing air analysis typically used for Food & Beverage, Pharma, OSHA Grade D, Grade E, US Navy Diving and more. Available for loan or purchase. . We provide international standards and methods for sampling and the testing of compressed air, ambient air and pure gas delivery systems. This includes a multitude .

practice in the food industry. These principles are designed to ensure the quality of the final product by identifying . ISO 8573-7 Compressed air - Test method for viable microbiological contaminant content ISO 22000 Food safety management systems - Requirements for .Compressed air testing should be a fundamental safety . mechanism for your facility, like fire extinguishers and . PPE. To ensure that your air systems meet the new . Air quality testing will be required in many food industry sectors, such as: • Primary plant production • Primary animal production • Aquaculture • Food manufacturingWe offer ISO 8573-1 and ISO 8573-7 compressed air testing options. . Food Grade Air; Food Packaging; Instrument / Nuclear; Medical Device; Pet Food; Pharmaceutical; . ISO 8573 is used widely throughout the compressed air industry, acting as a common language available to the manufacturer, compressed air system supplier, and compressed air .

cobb sizing test

cobb sizing tester

Resultado da 探索 Minecraft. Minecraft 是一款由方块、生物和社区组成的游戏。. 方块可以用来改变世界的形状或建造出新奇的作品。. 你可以与生物战斗或将其驯服,具体取决于你的游戏风格。. 无论是独自体验史诗般的冒险,还是与朋友一起,总有一个适合你游戏的方法。. 但 .

compressed air testing food industry|validation of compressed air